It’s been too long since I’ve had time to post anything, so

my apologies in true Canadian fashion. Getting wheel packages spec’d, ordered,

and built for my new Rugged Wheels business has taken much of my time outside

an already full commitment to my day job. However, it hasn’t been all work.

Thanks to rainy cool weather lately, where it hasn’t been cold enough to go fat

biking and yet it’s been too cold/wet/muddy for other riding, it’s been a

perfect time to show the WR250R some love and complete its 21,000 km service.

From this:

To this:

...and hopefully back again later.

According to the manual, 21,000 km is a major service interval.

Besides the usual stuff like oil change, cleaning the air filter, lubing

cables, etc., it’s time to inspect bearings, replace brake hoses, flush coolant, repack the

headset, touch up some rust spots on the frame, and do some other deeper inspections.

New chain sliders are always welcome. This is the third set on the bike. Wear was high (not surprising given the mud in my area) but appears to be even, suggesting chain line and tension are OK.

In the hopes of tackling some

more adventurous rides next year, I’ve also taken this opportunity to improve

some key parts of the bike.

Wheels

As reported earlier, I’ve built up a

rather nice set of new wheels around SM Pro hubs, rims, and Bulldog spokes (all of which I am now importing

as a dealer for SM Pro). Although I only managed to get in a few short test rides before my season ended, the improved handling that these properly

tensioned and balanced wheels gave the WRR was immediately apparent. Steering

and suspension felt a lot more crisp, probably a direct consequence of the

higher wheel stiffness that using heavier gauge spokes and higher tensions

achieved.

I’ve also rebuilt the original hubs into a second set of

wheels with the same SM Pro rims and Bulldog spokes. These wheels will be shod

with a set of Mitas knobbies oriented to 80% road use for those longer trips

where any dirt is likely to be just gravel roads. The first set of wheels will

keep full DOT knobbies, an MT-21 up front and D606 in the rear.

For gearing, I’ve decided to stick with a 47T Dirt Tricks

rear sprocket (one of the gorgeous new zirconium-plated models; I'm also a dealer for these now), but change the

front sprocket for a 14T (for road-oriented riding) and maybe revert to my

current 13T for off-road oriented riding.

14/47 is still a little shorter than

stock 13/43 gearing, so I’m hoping I can get away with just the one ratio. In

any case, alternating between 13T or 14T up front shouldn’t require a different

chain length, just an axle adjustment.

Suspension

A frequent complaint with the WRR is that the shock has

intrinsically poor rebound characteristics—even when you crank down the rebound

setting.

This video explains it well, and it certainly captures my own

experience. It’s frustrating to not be able to find a good set-up, despite having

good success dialing in my mountain bike suspension.

Clearly, motorcycle suspension tuning is a subtle art beyond

my available means of time, budget, and patience. So off went my forks and

shock to John Sharrard at

Accelerated Technologies near Peterborough, for his

tuning expertise. Although John prefers to receive the whole bike when tuning, that wasn’t

practical for me, so instead, he ran some tests on my parts, took them apart to

have a look at the internals, and called me to discuss a tuning strategy.

John feels the forks have a pretty decent set-up already.

However, they could benefit from some revalving of the “comfort shim” and

adjacent shims that together provide initial compliance to small-amplitude,

high-frequency bumps. These shims form one of two valving stages in the WRR

fork. The second stage of shims provides large bump compliance once you’ve

blown through the first stage. Both stages will be tweaked together (softening

the first stage and hardening the second stage) to provide more initial

responsiveness, a smoother transition between where small bump compliance ends

in the first stage, and more big-hit compliance. In addition, John recommends

using Motul 5-wt fork oil with this set-up. Although I’d used Spectro 5-wt in

my last fork service, John measured the viscosity as-received and found it was

closer to 30-wt. Not sure what happened there.

For the shock, John advised against a piston and valving

upgrade (e.g. using a Gold revalving kit, which is often recommended in online

discussions). He feels that the stock piston has adequate porting for my riding

style, and changing it would only introduce another tuning variable that would

make it harder to identify an optimal solution.

Instead, he is going to rebuild the valving around the strategy of replacing

the stock spring with a higher-rate (stiffer) spring, coupled with valving to

achieve higher compression and rebound valving to match the stiffer spring, but

then running the rebound more open. This approach should decrease preload on

the spring compared to the stock spring, but achieve lower energy and

compression of the nitrogen. In short, it allows not running the system so hard

(i.e. to try to overcome the original valving design flaws), which in turn

should improve compliance and allow more adjustability of the damping through

the clickers.

Incidentally, John measured the nitrogen pressure to be 145

psi (vs. spec of 150 psi), which is pretty good considering there’s 21,000 km of

dual-sport riding on the shock. He also thought the forks were pretty clean inside considering all the mud I've run through in the last 13,000km since last service.

With any luck, there will be a repeat of tropical Christmas

weather like last year, that will allow me to test-ride the suspension before

the full grind of winter sets in.

Brakes

The 21,000 km service indicates that the brake lines should

be replaced. Although mine appear to be in good shape (and I replaced the

pistons and seals last year), they are seven years old and that alone is enough

of a reason for me to replace them.

HEL Performance Canada sells gorgeous braided stainless

brake lines for a very reasonable price, and you can customize their appearance

to match your bike.

These lines came with banjo bolts and crush washers, but

the bolts were about a ¼” too short so I reused the stockers. Fit seems pretty

good, and from prior experience they are certain to improve brake feels.

Skid plate

Aluminum skid plates are not just awesome at deflecting

rocks, they also reflect engine noise in a way that is tiresome on long rides.

Prior experiments with different sound dampening materials and methods to bond

them to the aluminum have all proven to be failures, as the detached rubber

here clearly shows.

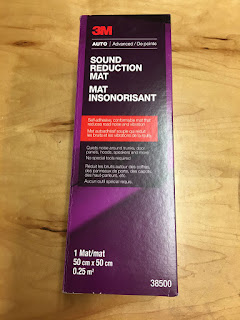

My latest iteration is to try this 3M bitumen-based

soundproofing material that I bought at Canadian Tire.

Preferably it would have

an aluminum facing (like the Dynamat I used on the wings of the skid plate) to reflect heat and reduce the chance of

getting trail crud embedded in the material. However, the adhesive seems super

strong so it’s worth a try. Based on whacking the skid plate with a hammer,

this stuff certainly dampens any ringing noise.

Fuel tank

With many more months before the road salt is gone and I can

ride the WRR again, I may pull the trigger on ordering a larger gas tank (~11L)

to gain some extra range. Currently I’m relying on a 1-gallon (3.8L) RotoPax

mounted on my rear rack for extra range over the 7.2L stock tank. While I

rarely need to dip into the RotoPax, having the option of confident 400km range

all-in would reduce range anxiety, especially when exploring.

Whole new bike?

Ah yes: the perennial question of "is it time to replace my bike?" Considering I'm only halfway to the first valve inspection (at 42,000 km) and don't have the budget for a new ride and its unknown shortcomings, beyond installing a larger tank it probably doesn’t make financial

sense to spend any more money on upgrading my WRR. When it is finally time to replace

it, there are likely to be many interesting new options for

small-displacement DS bikes, like the CRF250L Rally (which, however, is heavier and less powerful than the WR250R). Or hopefully something in

the 300-400cc range to give that extra bit of power for inevitable highway

riding.